Magnetorquer Design Parameters and Selection Criteria: Performance, Trade-offs, and System Specification

Authored by Afan Huang

Selecting the right magnetorquer for your spacecraft mission requires more than understanding fundamental operating principles. It demands careful analysis of mission-specific constraints, performance requirements, and operational environment. While our previous articles explored how magnetorquers work and their applications across different mission types, this article focuses on the critical engineering decisions that determine optimal magnetorquer specifications.

〈Related Reading:Magnetorquer: Principles and System Integration for Satellite ADCS〉

〈Related Reading:Magnetorquer Functions, Configurations, and Applications in Satellite Missions 〉

Mission designers face multiple competing priorities: maximizing control authority while minimizing mass, achieving sufficient magnetic moment within power budgets, and ensuring reliable thermal management throughout the mission lifetime. The selection process must also account for orbital environment factors, as Earth's magnetic field strength and geometry vary significantly with altitude and inclination, directly impacting magnetorquer effectiveness.

This article examines the key design parameters and selection criteria for magnetorquer systems, from calculating required magnetic dipole moments to evaluating trade-offs between power consumption, mass constraints, and thermal management. Whether you're designing a university research satellite or a commercial constellation, understanding these considerations will help you specify magnetorquers that meet mission requirements while optimizing spacecraft resources.

What Is Magnetic Moment and How Does It Work in Satellite Systems?

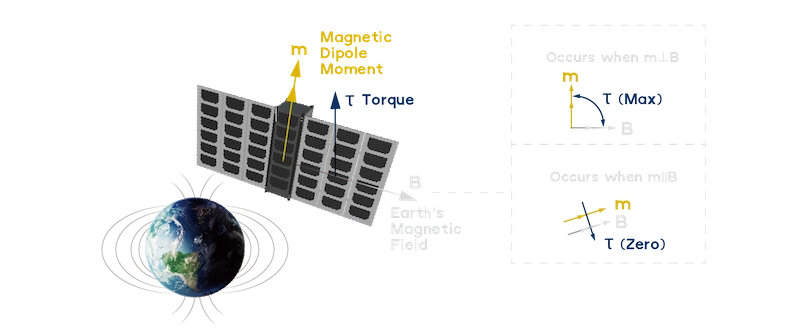

As established in our foundational article, magnetic moment (m) represents the strength of a magnetorquer electromagnetic field, measured in ampere-meter squared (A·m²). When this magnetic dipole interacts with Earth's ambient magnetic field (B), it produces a torque (τ) according to the cross-product relationship τ = m × B. The magnitude of this torque determines the magnetorquer's control authority: its ability to change the satellite's orientation.

For mission design purposes, the critical insight is that higher magnetic moments generate greater control torques, enabling faster attitude maneuvers and more effective disturbance rejection. However, achieving higher magnetic moments requires trade-offs in mass, power consumption, and physical size. The following sections explore how to balance these competing factors to select magnetorquers that meet mission requirements without over-constraining spacecraft design.

Design and Selection Considerations for Magnetorquers

Designing magnetorquers for spacecraft missions requires balancing multiple competing factors to achieve optimal performance within strict constraints. Key design parameters include magnetic dipole moment magnitude (which determines control authority), power consumption (which impacts available satellite resources), mass and volume limitations (which affect payload capacity), coil winding density and geometry (which influence efficiency), and thermal dissipation capability (which ensures reliable operation). Each of these factors interacts with the others, requiring a systems engineering approach to reach the best compromise for specific mission requirements.

Magnetic Dipole Moment and Torque Requirements

Defining Mission Requirements

The magnetic dipole moment is the fundamental performance specification for any magnetorquer, as it directly determines the control torque available for attitude maneuvers. Design begins with defining mission requirements: what angular rates must be controlled, how quickly must the satellite detumble after deployment, what pointing accuracy must be maintained, and what disturbance torques must be counteracted. These requirements translate into minimum torque specifications, which combined with the expected orbital magnetic field strength determine the required magnetic dipole moment through the relationship τ = m × B.

-

τ = Torque (control authority)

-

m = Magnetic dipole moment (magnetorquer output)

-

B = Earth's magnetic field

3D diagram illustrating the τ = m × B relationship

Example Calculation and Considerations

For example, a satellite in a 500 km low Earth orbit experiences magnetic field strengths of approximately 20-40 μT. To generate a torque of 1 μNm (sufficient for basic attitude control of a small satellite), a magnetorquer must produce a magnetic moment of roughly 0.025-0.05 A·m² when oriented perpendicular to the field. Mission designers must account for worst-case scenarios where the magnetic field is weakest and consider that three-axis control requires coordinated operation of multiple magnetorquers. The design process involves calculating maximum required torques across all mission phases (detumbling, acquisition, maintenance, slew maneuvers) and sizing magnetorquers with appropriate margin to ensure adequate control authority throughout the orbital environment. Understanding these torque requirements early in the design process prevents under-specification that could jeopardize mission success or over-specification that wastes valuable satellite resources.

Power Consumption and Thermal Management

Resistive Heating and Wire Selection

When current flows through magnetorquers windings, resistive heating occurs according to P = I²R, where power dissipation increases with the square of the current. This thermal energy must be effectively managed to prevent overheating that could damage the coil insulation, degrade magnetic properties, or affect nearby sensitive components. Design optimization requires balancing wire gauge selection: thicker wire reduces resistance and heating but increases mass and reduces the number of turns possible in a given volume, while thinner wire allows more turns (increasing magnetic moment per ampere) but increases resistance and thermal losses.

Thermal Management Strategies

Effective thermal management strategies include selecting wire insulation materials rated for expected operating temperatures, designing coil geometries that maximize surface area for passive heat dissipation, incorporating thermal interfaces to transfer heat to satellite structures or radiators, and implementing duty-cycle control strategies that limit continuous operation time. For spacecraft with limited thermal management capability, power consumption directly constrains magnetorquer performance.

Worst-Case Scenarios and Safety Measures

Designers must calculate worst-case thermal scenarios, considering simultaneous operation of multiple magnetorquers during aggressive maneuvers and the varying thermal environment as the satellite transitions between eclipse and sunlight. Modern MTQ Board designs often incorporate temperature monitoring and current limiting to protect against thermal damage, providing an additional safety layer. The power-thermal trade becomes particularly critical for missions with tight power budgets or operating in thermally challenging orbits, requiring careful analysis to ensure magnetorquer operation remains within safe limits while meeting attitude control performance requirements.

Thermal management of magnetorquers

Structural and Mass Constraints

Impact of Mass on Spacecraft Design

In spacecraft design, mass is always at a premium. Mass allocated to attitude control reduces available capacity for payload instruments, communication systems, or power generation. Magnetorquer design must therefore achieve required performance within strict mass budgets. This constraint directly influences material selection, coil configuration, and the choice between air core and iron core designs.

Rod-Shaped Magnetorquers and Mass Efficiency

Rod-shaped magnetorquers offer favorable mass efficiency for their performance, as the elongated geometry maximizes magnetic moment while fitting efficiently within spacecraft structures. Iron core designs provide superior performance per unit mass compared to air cores, though the core itself adds weight that must be justified by the performance gain.

Structural Integration Considerations

Structural integration considerations include mounting provisions that ensure rigid attachment without adding excessive mass, routing of electrical connections that doesn't compromise structural integrity, and placement that maintains the satellite's center of mass within acceptable limits. For spacecraft requiring three-axis control, multiple magnetorquers must be positioned appropriately, requiring careful layout planning to optimize both magnetic performance and structural efficiency.

Design Optimization and Advanced Techniques

The design process involves iterative optimization: starting with performance requirements, selecting a preliminary design, calculating mass and structural impacts, and refining the design until an acceptable balance is achieved. Advanced missions may employ topology optimization or custom coil geometries to extract maximum performance from minimum mass, though such approaches must be balanced against increased design complexity and manufacturing cost.

Mission and Orbital Environment Considerations

Orbital Magnetic Environment

Different orbital regimes present vastly different magnetic environments, fundamentally affecting magnetorquer design requirements. Low Earth orbit (LEO) missions at 400-600 km altitude experience relatively strong magnetic fields (25-50 μT), allowing moderately sized magnetorquers to generate substantial control torques. Sun-synchronous orbits (SSO) at 600-800 km altitude see slightly weaker fields but offer predictable magnetic geometry that simplifies control algorithm design. Higher altitude missions or those approaching equatorial orbits encounter weaker and more variable magnetic fields, requiring more powerful magnetorquers or acceptance of reduced control authority.

Mission Profile and Performance Requirements

Mission profile significantly impacts design decisions. A technology demonstration satellite with relaxed pointing requirements can utilize smaller, lighter magnetorquers, while an Earth observation mission demanding precise nadir pointing needs higher-performance actuators. Satellites requiring rapid attitude slewing or operating in orbits with significant disturbance torques (such as those with large atmospheric drag or solar pressure effects) need magnetorquers with greater magnetic moments.

Orbital Inclination and Control Authority

The orbital inclination affects magnetic field geometry: polar orbits provide more consistent magnetic control authority, while equatorial orbits experience periods of reduced effectiveness when the magnetic field is nearly parallel to certain satellite axes. Designers must simulate attitude control performance across the full orbit, identifying worst-case scenarios and ensuring magnetorquers provide adequate authority even under challenging geometric conditions.

Design Robustness and Margin

This analysis often reveals that missions benefit from magnetorquers sized beyond minimum theoretical requirements to provide robustness against uncertainties in the magnetic environment, disturbance modeling, and actuator performance. Understanding these orbital and mission-specific factors ensures magnetorquer selection appropriately matches the operational reality the satellite will encounter throughout its mission life.

Why Choose Tensor Tech's Magnetorquer MTQ Series Products?

TensorMTQ series

Heritage and Proven Reliability

Tensor Tech's magnetorquers, TensorMTQ series, bring flight-proven reliability to satellite missions. With extensive heritage in actual space missions, these magnetorquers have demonstrated their durability and performance in the harsh space environment. The company's commitment to quality ensures that each unit undergoes rigorous testing and qualification, providing mission designers with confidence that their attitude control system will perform as expected throughout the mission lifetime.

Comprehensive Product Range

The TensorMTQ series offers flexible solutions tailored to different CubeSat configurations and mission requirements. From compact 1U-compatible designs to more powerful systems for larger platforms, Tensor Tech provides magnetorquers that match your specific needs. The product line includes both individual magnetorquer rods and complete MTQ boards with integrated driver electronics, allowing mission designers to choose the level of integration that best fits their spacecraft architecture.

〈Related Reading:Cube Satellites: Unlocking Space for Everyone〉

Optimized Performance Specifications

Tensor Tech's magnetorquers are engineered to deliver maximum magnetic moment within minimal mass and volume budgets. The carefully designed coil configurations and core materials provide excellent efficiency, generating strong magnetic fields while consuming reasonable power levels. This optimization is crucial for CubeSats where every watt and gram must be justified, ensuring that attitude control doesn't compromise other mission capabilities.

〈Related Reading:CubeSat Satellites: Driving Innovation in Small-Scale Space Missions〉

Customization Capabilities

Understanding that no two missions are identical, Tensor Tech offers customization options to meet specific mission requirements. Whether you need a particular magnetic moment range, specific mounting interfaces, or custom operating voltage ranges, the engineering team can adapt the MTQ series products to your needs. Production lead times for customization are compatible with compressed satellite development timelines. This flexibility ensures seamless integration with your spacecraft design without forcing unnecessary compromises.

Integrated System Approach

The MTQ Board products exemplify Tensor Tech's integrated system philosophy. Rather than simply providing magnetorquer coils, these boards combine the electromagnetic actuators with intelligent driver electronics, creating a complete subsystem that interfaces cleanly with your onboard computer. This approach simplifies integration, reduces development risk, and ensures optimal performance through matched components designed to work together from the outset.

Conclusion

Magnetorquers stand as essential components in the satellite attitude control toolkit, providing reliable, efficient, and compact solutions for orientation management in space. Their ability to stabilize satellites, perform detumbling operations, and enable momentum dumping makes them indispensable for mission success, from initial deployment through years of operational service.

For mission designers seeking dependable attitude control solutions, Tensor Tech's TensorMTQ series products deliver the performance, reliability, and flexibility needed to meet diverse mission requirements. With proven spaceflight heritage, comprehensive product options, and customization capabilities, Tensor Tech's magnetorquers solve attitude control challenges while respecting the constraints inherent to satellite platforms.

Whether you're developing your first CubeSat or designing an advanced constellation, choosing high-quality magnetorquers from the TensorMTQ series ensures your spacecraft maintains precise control of its orientation, enabling successful mission outcomes in the demanding environment of space. Ready to specify the optimal magnetorquer for your mission? Contact Us today to consult with Tensor Tech's engineering team and ensure your satellite achieves peak performance.