ADCS Testbed Innovations: Accelerate Your Satellite Development

Authored by Afan Huang

In satellite engineering, verification and validation of subsystem performance under realistic conditions are critical to mission success. Among these subsystems, the Attitude Determination and Control System (ADCS) is particularly sensitive to dynamic, time-dependent inputs from space, including inertial motion, Earth’s magnetic field, and orbital mechanics. Since these conditions are difficult to replicate in traditional laboratory environments, an ADCS TestBed becomes a necessary tool.

〈Related Reading:Attitude Determination and Control Systems (ADCS): An In-Depth Analysis from Sensing to Control〉

What is an ADCS Testbed?

An ADCS TestBed is a ground-based experimental platform designed to simulate key physical aspects of the space environment. It enables engineers to integrate ADCS hardware (such as sensors, actuators, and embedded control software) into a looped simulation setup for functional testing prior to flight.

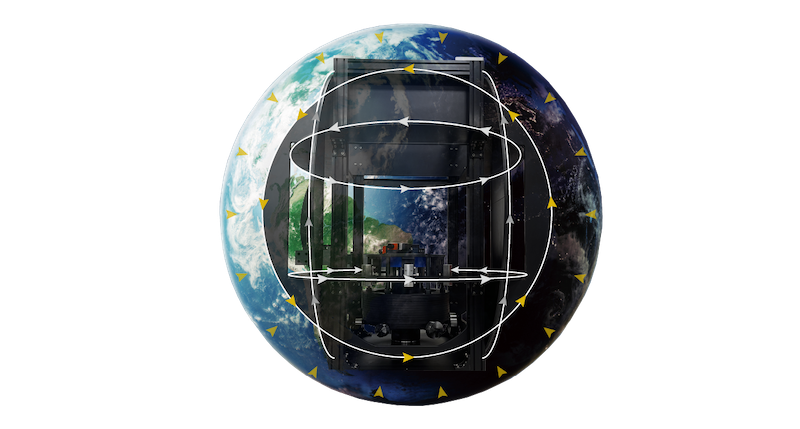

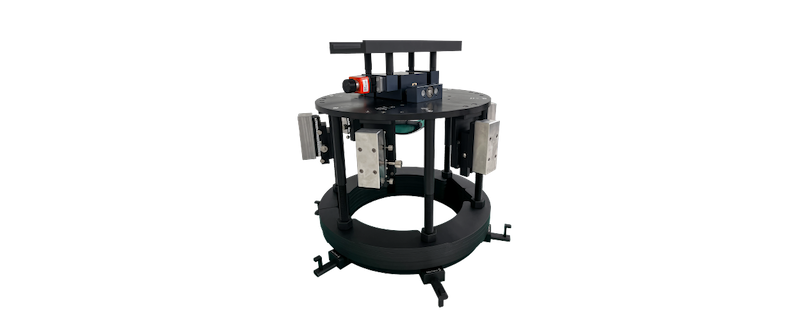

ADCS Testbed with Helmholtz cage simulating Earth's magnetic field

This article introduces the role of the ADCS TestBed in satellite development and explains how it supports early-stage system integration, algorithm validation, and mission-specific tuning.

Why Do Satellite Developers Need an ADCS Testbed?

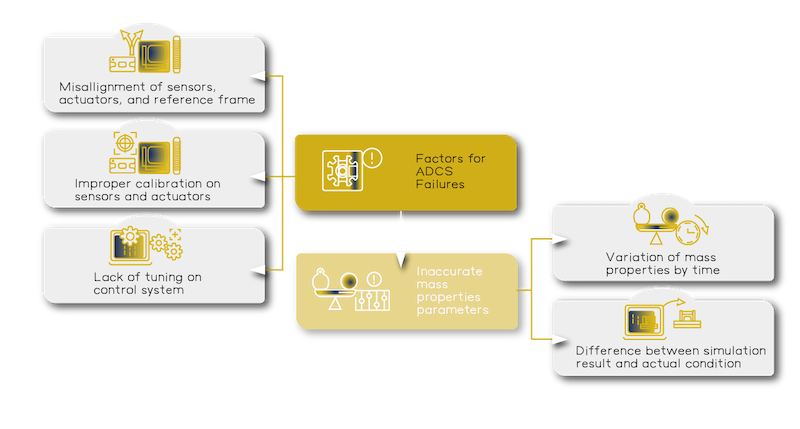

Building a reliable satellite attitude determination and control system (ADCS) requires testing and repeated iteration. In satellite missions, even minor deviations in attitude control can lead to mission failure. Common issues in ADCS include unexpected steady-state errors, longer time required to reach a stable state, and instability in the control response. These issues often originate from problems that only become apparent during hardware integration or system-level testing. Contributing factors include sensor and actuator miscalibration, misaligned reference frames, and, importantly, inaccurate mass properties.

〈Related Reading:Keys toward precise attitude control〉

Common Factors of ADCS Failures

Impact of Quality Characteristic Data on Control Algorithms

Mass properties, specifically total mass, center of mass (COM), moment of inertia (MOI), and product of inertia (POI), are critical inputs for control algorithms. These values directly influence the satellite's dynamic response and determine how well the control system can perform during attitude maneuvers. Yet, they are frequently approximated using CAD simulations, which introduce two main problems: simulation error and time-dependent changes.

Potential Risks of Simulation Errors and Time Variations

Simulation errors are caused from uncertainties in material densities, machining tolerances, and assembly imperfections. Time-varying changes arise from thermal deformation or propellant consumption, both of which alter the satellite’s mass distribution after the initial simulation. As a result, the actual system behavior may be inconsistent with the model used during control design.

To address these challenges, engineers use an ADCS TestBed as a ground-based experimental platform designed to simulate orbital conditions and measure physical parameters with fidelity. With tools like an air-bearing platform, engineers can measure actual COM and MOI of a fully assembled satellite, feeding real values into the control algorithm. The ADCS TestBed enables realistic, closed-loop testing with hardware and software, allowing issues to surface and be resolved early in development.

How an ADCS Testbed Speeds Up Development

Dramatically Shorten Development Cycles through Immediate Feedback

One of the greatest values of an ADCS TestBed is how it enables hardware-in-the-loop testing early in development. Developers can integrate sensors, actuators, and embedded software onto the ADCS TestBed and run realistic orbital simulations long before flight hardware is finalized.

This feedback loop allows engineers to catch integration issues, algorithmic errors, or hardware limits at a much earlier stage. Instead of waiting months for expensive field tests or launch results, developers can run iterative cycles daily. With the ADCS TestBed, failure becomes part of the learning process without risking a satellite in orbit.

Hardware-in-the-Loop (HiL)

Satellite ADCS Development Requires Real Hardware Verification

The development of a satellite’s ADCS involves iterative design, testing, and refinement across software algorithms, sensor calibration, and actuator tuning. Traditionally, much of this process is performed in simulation. However, software-only environments cannot fully capture the complex and dynamic status between physical hardware and environmental interactions. As systems become more integrated and dynamic, early-stage verification must include real hardware-in-a-looped test environments. This is where an ADCS TestBed becomes critical.

ADCS Testbed Provides a Complete Simulation and Physical Component Testing Platform

An ADCS TestBed enables engineers to conduct hardware-in-the-loop testing by integrating actual flight components such as reaction wheels, magnetorquers, gyroscopes, and sun sensors, into a simulated orbital scenario. The air-bearing platform of the ADCS TestBed allows for frictionless rotation, mimicking spacecraft motion in free space. Magnetic field simulators (e.g., Helmholtz cages) replicate Earth’s field at varying orbital positions, while solar simulators provide directional light input to test sensor response.

This setup supports rapid iteration of control algorithms, including attitude estimation filters and feedback loops. Instead of waiting for flight tests or relying solely on numerical models, teams can evaluate how the actual control logic responds to real sensor input and actuator commands. Errors in dynamics modeling, software timing, or hardware interfaces become visible immediately. Adjustments can be made within days rather than months, reducing the time between design cycles.

〈Related Reading:An introduction to fine sun sensors〉

Simulate a space environment

Another key advantage is the ADCS TestBed provides a platform to validate mass property estimates through experimental measurement, closing the loop between design assumptions and physical reality.

Overall, the ADCS TestBed enables transition from simulation to hardware verification. It helps ensure that the control system will operate reliably under similar space conditions.

What Should a Complete ADCS Testbed Include?

An ADCS TestBed consists of multiple functional modules designed to simulate critical aspects of the space environment and system dynamics.

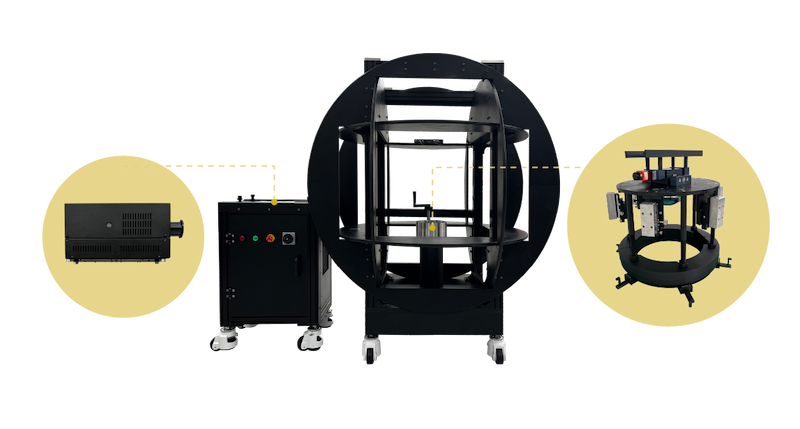

Tensor Testbed

Air-Bearing Platform

At the core of the ADCS TestBed, the air-bearing platform allows near-frictionless two- or three-axis rotation, simulating free motion in space. It provides a physical environment where reaction wheels, control moment gyroscopes (CMGs), and torque rods can be tested for responsiveness and stability.

〈Related Reading:What Is a Control Moment Gyroscope (CMG)? A Powerful Solution for Satellite Attitude Control〉

〈Related Reading:Revolutionizing Satellite Attitude Control: Spherical Motor-driven Control Moment Gyroscope〉

Air-Bearing Platform

Triaxial Helmholtz Cage

This magnetic field simulator generates controllable magnetic environments, enabling precise testing of magnetometers and magnetic torquers. It can emulate Earth’s magnetic field at any point in orbit, offering validation for magnetometer-based attitude determination.

Triaxial Helmholtz Cage

Solar Simulator

Simulating sunlight is essential for fine sun sensor verification and calibration. A solar simulator provides adjustable intensity and angle control, allowing accurate testing of sun sensor algorithms, solar panel orientation.

Solar Simulator

Software

The software in an ADCS TestBed handles scenario setup, real-time control execution, sensor and actuator interfacing, and data logging. It synchronizes all ADCS TestBed modules and supports hardware-in-the-loop simulation by connecting physical components with control algorithms. Automation features allow engineers to run repeatable test cases and perform regression testing across different mission profiles. Post-test analysis tools provide access to telemetry, enabling the evaluation of control accuracy, stability margins, and system response.

Software

Common Challenges in Building an ADCS Testbed

Creating an ADCS TestBed comes with its own set of engineering hurdles. Precise motion simulation demands low-friction hardware, but also highly accurate sensors. Misalignment between modules, electromagnetic interference, or latency in feedback loops can all compromise results.

Synchronization between physical modules and digital models also introduces complexity. To overcome this, many developers adopt modular architectures, real-time controllers, and calibration routines that align the ADCS TestBed environment with the expected orbital conditions.

How to Customize an ADCS Testbed for Different Missions

Each satellite mission presents unique attitude control requirements based on its orbit, payload configuration, control strategy, and mission duration. A fixed setup of ADCS TestBed cannot accommodate this variability. Therefore, adaptability is a key requirement in ADCS TestBed design.

Modular architecture allows engineers to reconfigure or extend the ADCS TestBed according to mission-specific needs. For example, satellites operating in low Earth orbit may require higher-fidelity magnetic field simulation, while deep-space missions might prioritize precision sun sensor testing. The ability to replace or adjust components, such as swapping different actuator types, adjusting air-bearing configurations, or modifying software parameters, ensures that the ADCS TestBed remains relevant across various mission profiles.

〈Related Reading:How to pick up a suitable CubeSat ADCS〉

Build a Reliable ADCS with Tensor Tech’s ADCS Testbed

Tensor Tech provides an ADCS TestBed system, TensorTestBed, designed with modular architecture and scalability. It includes components such as an air-bearing platform, a three-axis Helmholtz cage, a solar simulator, and software interfaces to support a range of test configurations. The TensorTestBed system enables engineers to verify, test, and refine ADCS designs throughout the development process.

Tensor Tech’s ADCS TestBed system, TensorTestBed

〈Related Product Recommendations:ADCS TestBed〉

Conclusion

The complexity of satellite attitude control demands more than simulation-based validation. Many ADCS failures can be traced to unmodeled dynamics, inaccurate mass property estimates, or insufficient system-level testing. A well-constructed ADCS TestBed addresses these issues by enabling hardware-in-the-loop testing.

By incorporating modules such as air-bearing platforms, 3-axis Helmholtz cages, solar simulators, and configurable software, the ADCS TestBed supports direct measurement of key physical parameters, including center of mass and moment of inertia, which are often misestimated during the design phase.

Tensor Tech’s ADCS TestBed system, the TensorTestBed is developed to support these engineering requirements through a modular, scalable system architecture. It is not intended to replace simulation but to complement it by offering a physical layer of testing that captures effects often neglected in software-only environments.

Incorporating an ADCS TestBed early in the development cycle allows teams to detect integration issues, validate mission-specific configurations, and reduce uncertainty during the developing stage. For teams aiming to accelerate satellite development while improving system reliability, the ADCS TestBed is a necessary tool in the engineering workflow. To learn more or request a consultation, contact us today: Contact Us