Authored by Afan Huang

Why Satellites Need Better Attitude Control

As satellites grow smaller and missions demand faster, more agile response times, traditional attitude control systems struggle to keep up. This is where the Control Moment Gyroscope (CMG) stands out—offering high torque, fast maneuvering, and significant power savings over legacy systems like reaction wheels.

What Is a Control Moment Gyroscope (CMG)?

A Control Moment Gyroscope (CMG) is an actuator used in satellite Attitude Determination and Control Systems (ADCS) to generate precise rotational torque without expelling mass. Originally developed to address the limitations of reaction wheels, CMGs deliver superior performance through gyroscopic precession, offering enhanced torque authority and power efficiency.

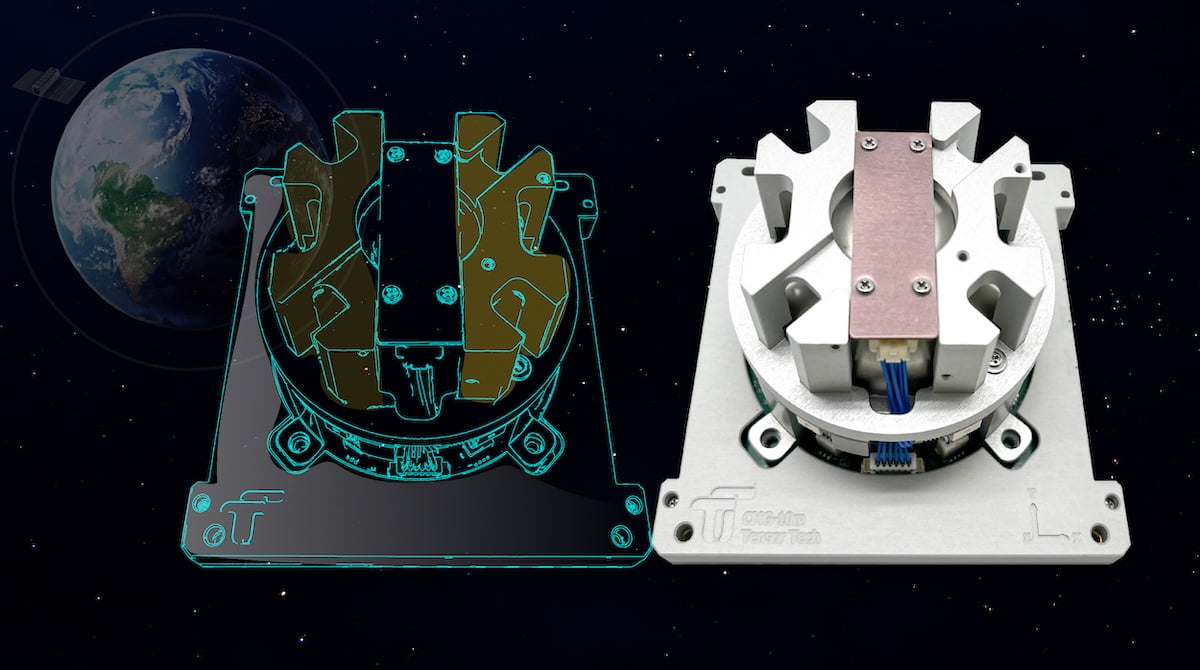

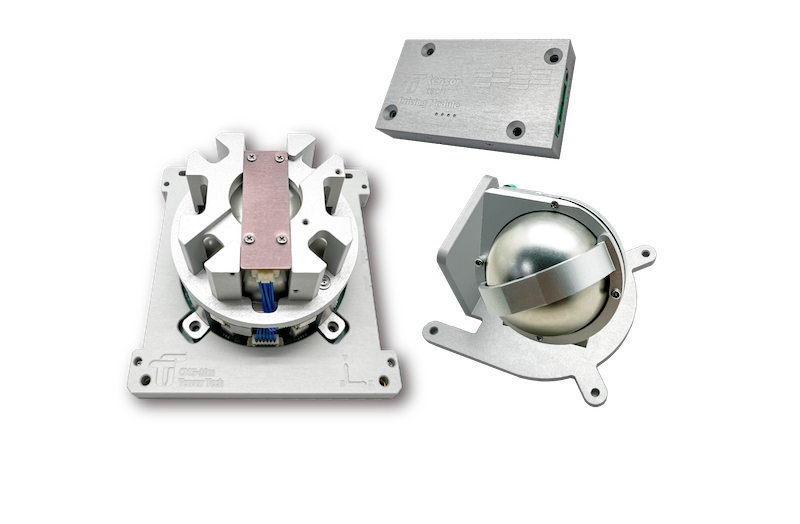

TensorCMG Products

Key Advantages of Control Moment Gyroscopes in Satellite Missions

-

High Torque Efficiency:Rapid response in attitude control.

-

Superior Power Efficiency:Minimal electrical power for significant torque.

-

Compact Angular Momentum Storage:Higher momentum density than reaction wheels.

-

Exceptional Maneuverability:Suited for fast, large-angle slewing.

-

Reliable Repetitive Slews:Well-suited for agile Earth observation and constellation phasing.

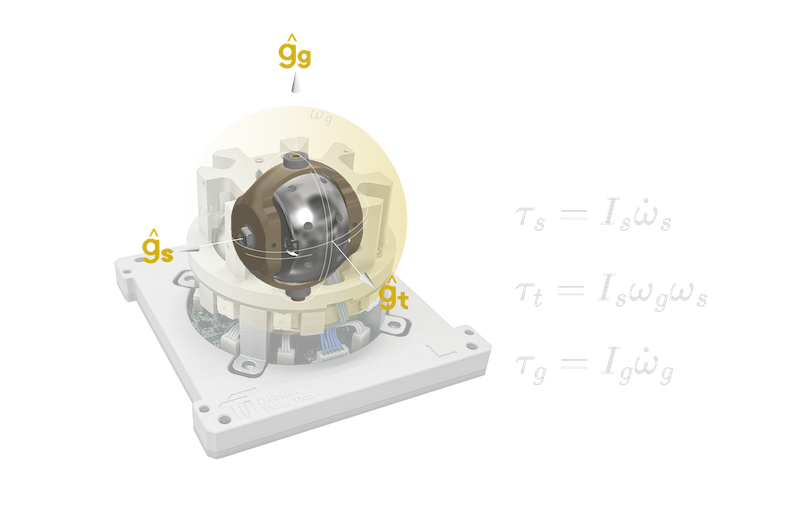

How Control Moment Gyroscopes Work: The Operating Principle

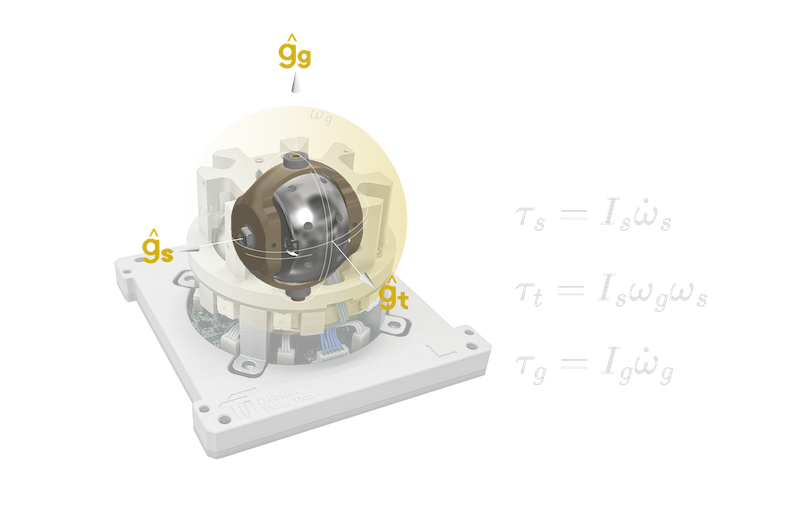

Most CMGs, especially the widely used Single-Gimbal CMGs (SGCMGs), use a high-speed spinning rotor mounted within a gimbal mechanism. The gimbal tilts the rotor to change the direction of its angular momentum, producing torque orthogonal to the rotor’s spin axis. This gyroscopic torque "Tg" is directed orthogonally to both the rotor spin axis and the gimbal tilt axis, enabling efficient torque production in a desired direction.

In addition, the torque "Ts" can also be produced by speeding up or slowing down the rotor. This means a variable-speed CMG can output torque in two degrees of freedom: one via gyroscopic precession, and the other via direct reaction wheel-like acceleration.

System Dynamics of CMG

Variable-speed CMGs (VSCMGs) allow even finer control by adjusting both gimbal angles and rotor speeds.

The torque generated is the result of a gyroscopic effect — specifically, the cross product of the rotor’s angular momentum and the gimbal's angular velocity.

Control Moment Gyroscope vs Reaction Wheel: Performance and Power Comparison

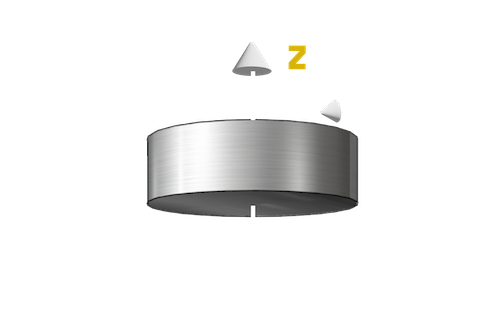

Reaction wheels generate torque by accelerating or decelerating a flywheel along one axis, making them simple but limited. Torque output is directly tied to power input, often requiring >200W for modest performance.

Reaction wheels generate torque along one axis

CMGs, by contrast, use gyroscopic torque generation. Because the output torque is nearly orthogonal to the rotor's angular velocity, they achieve better torque-per-watt ratios.

For example, a CMG can deliver similar torque as a reaction wheel using <10% of the power— a game-changer for satellites with tight energy budgets.

Types of Control Moment Gyroscopes

CMGs come in several types:

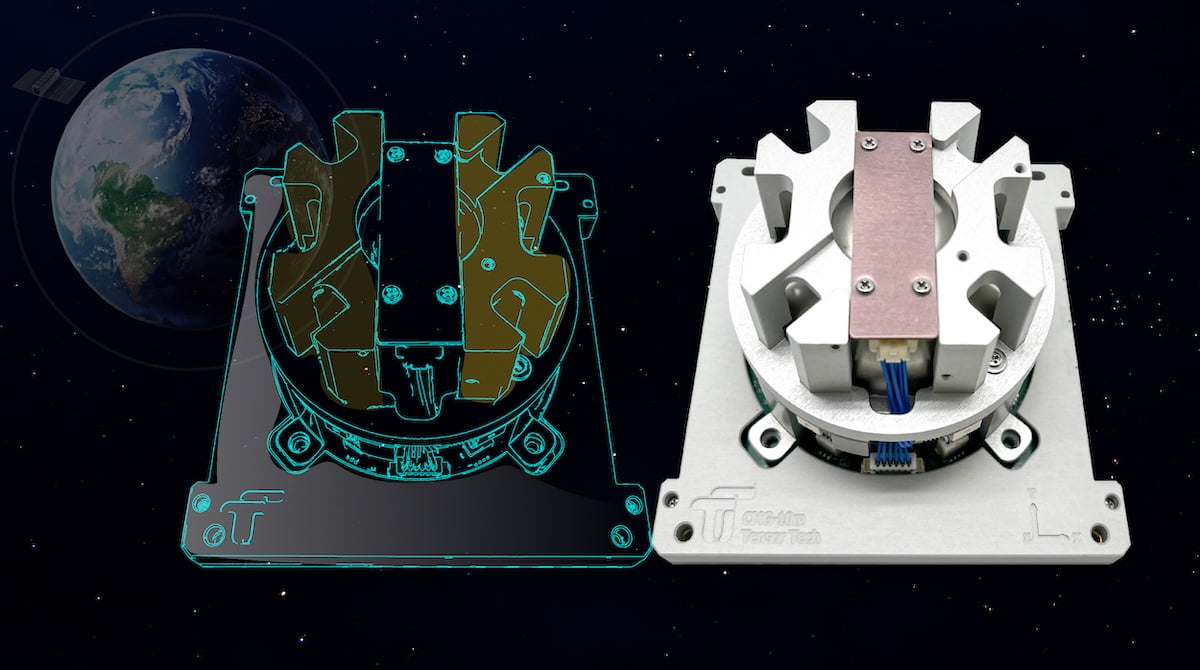

1. Single-Gimbal CMGs (SGCMG)

The most widely used type. It features one gimbal axis to tilt the spinning rotor. SGCMGs offer a strong balance of mechanical simplicity, reliability, and high torque output, making them well-suited for small and medium satellites. Tensor Tech adopts this architecture for its core CMG products.

2. Dual-Gimbal CMGs (DGCMG)

Adds a second gimbal axis, allowing more flexible torque vectoring and expanded maneuverability. However, DGCMGs are more complex, heavier, and can introduce additional singularities in control, making them less common in smaller spacecraft.

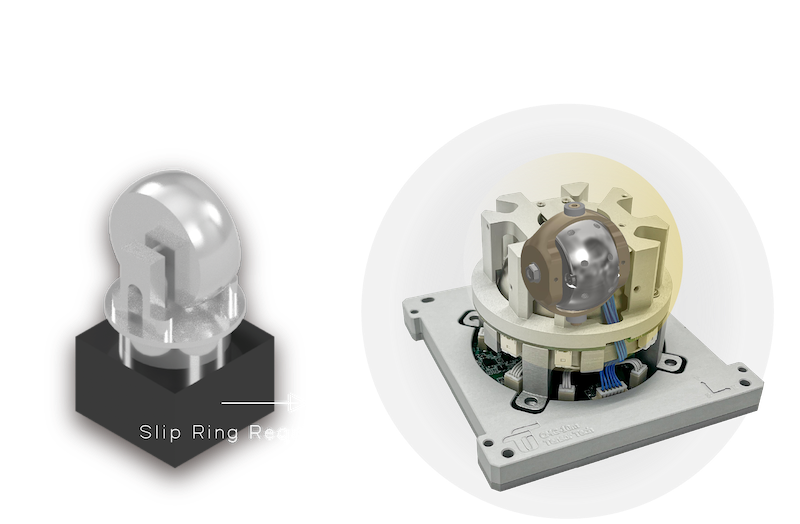

3. Variable-Speed CMGs (VSCMG) driven by spherical motor technology

Enhances torque control by dynamically adjusting both the gimbal angle and rotor spin speed. While offering the most flexible control capability, VSCMGs require more sophisticated electronics and control algorithms. Tensor Tech’s advanced variable-speed SGCMGs incorporate this approach using spherical motor technology to eliminate slip rings.

Traditional SGCMG vs. Variable-Speed SGCMG

Each type suits different mission needs, but Variable-Speed SGCMGs remain the preferred choice for most satellite ADCS systems due to their robustness, high torque-to-mass ratio, and ease of implementation. Tensor Tech leverages SGCMG principles while pushing innovation further with variable-speed enhancements and compact integration.

-

Lifetime and Speed-Varying Capability:Not limited by the slip ring

-

50% smaller than SGCMG:Due to the removed gimbaling motor

-

Spherical-Shaped CMG:Saves volume while skiing the CMG

More detailed information will be explored in our next blog article. Stay Tune!

Conclusion:The Future Is Control Moment Gyroscope

As satellite missions evolve in complexity and agility, CMGs are becoming the actuator of choice for next-gen ADCS. Whether for low Earth orbit microsatellites or high-agility platforms, CMGs deliver performance that legacy solutions can’t match.

Curious how CMGs can enhance your satellite’s performance? Learn more about Tensor Tech’s innovative CMG solutions and how our spherical motor-driven CMG is reshaping spacecraft agility.If you have any CMG needs, please contact us.

〈Related Product Recommendations:Control Moment Gyroscope〉

〈Related Reading:An introduction to fine sun sensors〉