Keys toward precise attitude control

Authored by Austin Chang, 2021.05

Revised by Afan Huang, 2025.09

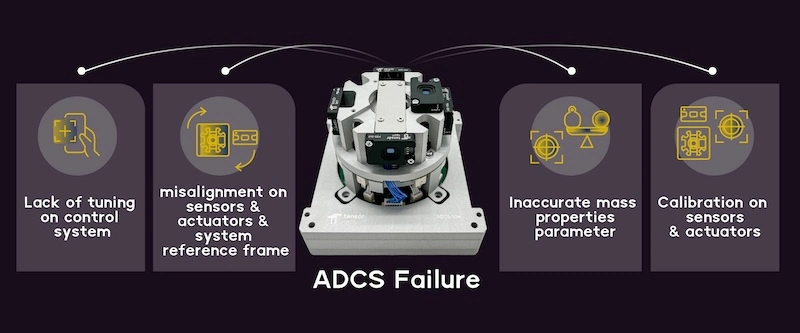

Failures of the attitude control system

In the complex world of satellite engineering, the Attitude Determination and Control System (ADCS) plays a crucial role in maintaining a satellite's orientation and stability. However, ADCS failures can manifest in various ways, from steady-state errors and prolonged response times to divergent control outcomes. While improper calibration of attitude sensors and actuators, along with misalignment between sensor, actuator, and system reference frames, are often culprits, two significant factors often fly under the radar: inaccurate mass properties and insufficient tuning of the attitude control system.

The Practical Role of Attitude Control in Space Missions

Before diving into the technical challenges, it's essential to understand why precise attitude control matters across different space applications. For communication satellites, maintaining exact orientation ensures optimal signal strength and coverage areas, directly impacting data transmission quality and service reliability. Earth observation satellites require milliarcsecond-level pointing accuracy to capture high-resolution imagery and maintain consistent ground track coverage for monitoring applications such as climate change, agricultural monitoring, and disaster response.

Two Critical Factors Affecting Attitude Control

Typically, engineers obtain mass properties through simulations using sophisticated Computer-Aided Design (CAD) tools like SolidWorks or Autodesk. However, the transition from simulation to reality is not always smooth. Two types of errors can emerge in practice: variations in mass properties over time and discrepancies between simulation results and the physically integrated hardware.

Simulation-Reality Gap

Discrepancies between simulation results and physically integrated hardware represent a significant challenge in satellite development. This gap arises from numerous factors, including inconsistencies in material densities, machining tolerances, assembly errors, and other unpredictable elements that accumulate during manufacturing and integration. These variables can cause the actual moment of inertia and center of mass to deviate significantly from CAD-based calculations. To address this challenge, obtaining accurate measurements of the assembled satellite's mass properties is crucial. This real-world data provides a baseline that can dramatically improve the accuracy of attitude control systems and bridge the gap between theoretical models and physical reality.

Variations in Mass Properties over Time

Mass properties of satellites can change throughout their operational life due to several dynamic factors. Thermal variation is a primary contributor, causing satellite deformation as different materials expand and contract at varying rates due to their differing thermal expansion coefficients. Additionally, flexible components such as solar panels can significantly alter mass properties during deployment and operation. Addressing these temporal variations typically requires embedding robust control techniques into the satellite's control logic. However, experience suggests that this issue becomes truly significant primarily for larger satellites, where the dynamic characteristics of flexible bodies dominate the spacecraft's overall behavior.

Factors for the failure of the attitude control system

Addressing these two critical factors requires different strategies but shares a common foundation: accurate knowledge of the satellite's mass properties - including total mass, center of mass (COM), moment of inertia (MOI), and product of inertia (POI). The inertia matrix, formed by the combination of MOI and POI, is fundamental to effective attitude control - a concept so central to our work that it inspired our company's name. For the simulation-reality gap, precise measurements of the assembled satellite provide the necessary real-world baseline. For temporal variations, robust control algorithms must accommodate changing properties throughout the mission lifecycle. Together, these approaches ensure that ADCS can maintain precise attitude control despite the inherent uncertainties in both manufacturing and operation.

The Practical Role of Attitude Control in Space Missions

Attitude control is not merely a technical requirement. It directly determines a satellite's ability to fulfill its mission objectives. Different types of space missions demand varying levels of attitude control precision, each with unique operational challenges.

Communication Satellites require precise antenna pointing to maintain reliable links with ground stations or other spacecraft. Even minor attitude errors can result in signal degradation or complete loss of communication. For geostationary satellites, maintaining accurate Earth-pointing orientation is essential for continuous service coverage, while inter-satellite links demand even tighter pointing accuracy to ensure data relay between spacecraft.

Earth Observation Satellites depend on highly accurate attitude control to capture high-quality imagery and maintain target tracking. Remote sensing missions often require pointing accuracy within fractions of a degree to ensure that instruments remain locked on specific ground targets. Agile satellites, designed for rapid retargeting, must execute precise attitude maneuvers while maintaining stability during image acquisition, making robust control systems absolutely critical.

Rendezvous and Docking Operations represent some of the most demanding scenarios for attitude control. During approach phases, spacecraft must maintain precise relative orientations while coordinating with target vehicles. Any attitude control failure during docking can result in mission-critical damage or complete mission failure, highlighting why accurate mass property knowledge and robust control algorithms are indispensable.

Navigation and Formation Flying missions require multiple satellites to maintain precise relative positions and attitudes. These distributed systems rely on coordinated attitude control across all spacecraft to function as a unified system, whether for GPS constellations maintaining global coverage or formation-flying missions conducting interferometric observations.

Understanding these practical applications underscores why addressing the simulation-reality gap and temporal variations in mass properties is not just an engineering exercise - it's fundamental to mission success across all domains of space operations.

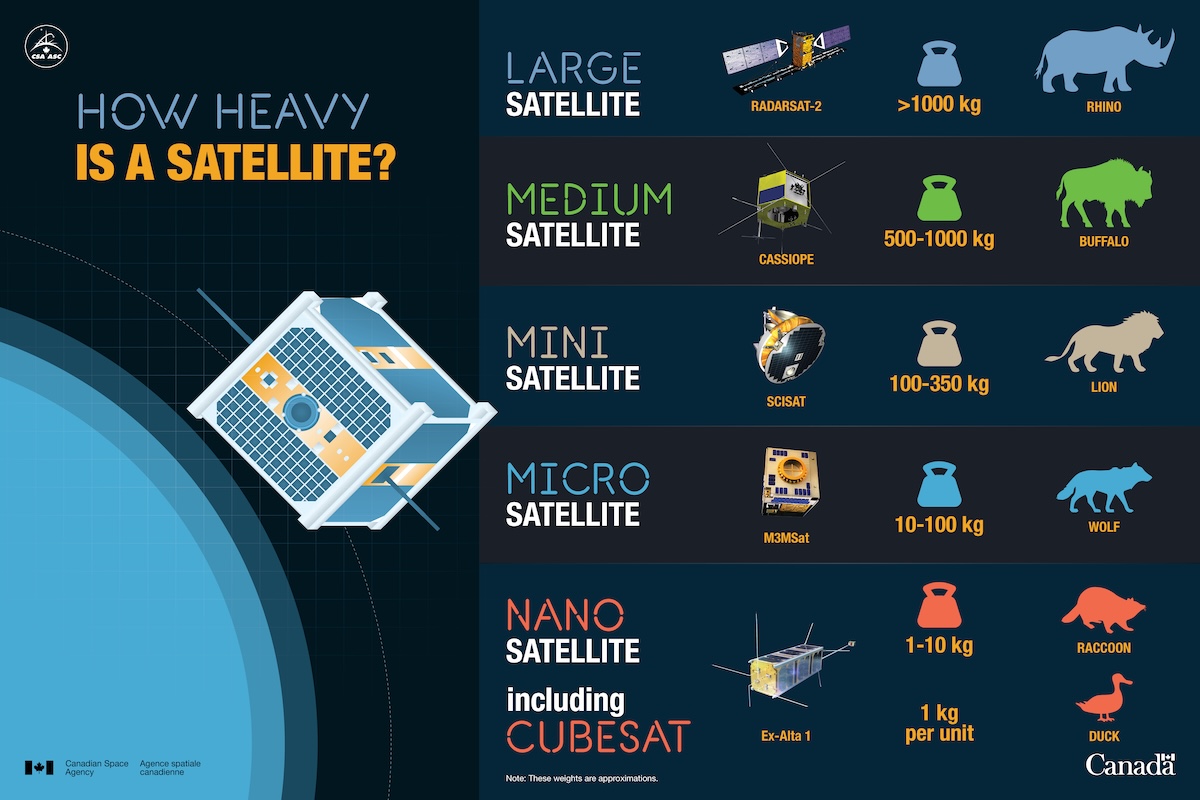

The mass of satellites in five categories

(The mini and medium satellites are categorized as small satellites.)

Source : What is a CubeSat. (2018). Canada.Ca. https://www.asc-csa.gc.ca/eng/satellites/cubesat/what-is-a-cubesat.asp

Tensor Tech’s Approach to Small Satellite Attitude Control

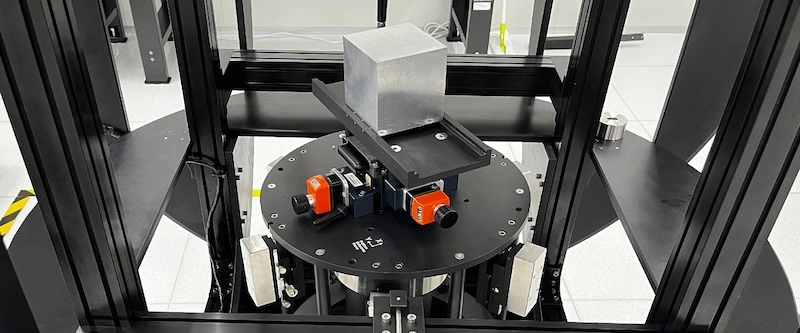

Recognizing the critical need for accurate mass property measurements, especially for smaller spacecraft, Tensor Tech has developed the TensorTestBed, an attitude determination and control system testbed. The TensorTestBed stands out in a market where most mass property measurement instruments are calibrated for objects weighing over 30kg. Our focus on nano-satellites fills a crucial gap in the industry, providing precise measurements for these increasingly popular smaller spacecraft.

Learn More

Want to explore Tensor Tech’s ADCS TestBed System?

〈Related Reading:What is a TestBed? Practical Application in Satellite ADCS〉

TensorTestBed, the satellite mass properties measurement and attitude control testing facility developed by Tensor Tech

Conclusion

Precise attitude control remains one of the most challenging aspects of satellite engineering, with mass property accuracy and proper system tuning serving as critical success factors. The TensorTestBed offers an effective solution for both our clients and internal teams to test the performance of their attitude control systems. Featured with a hemispherical air-bearing platform, the TensorTestBed provides one of the most accurate ways to simulate attitude control in a near zero-gravity environment on Earth. Without access to such specialized equipment, many struggle to properly tune their attitude control systems, resulting in suboptimal performance.Contact Us.